HVIL Connector

MSD Not to Be Ignored in Electric Vehicles

What is the MSD (Manual Service Disconnect)?

Manual Service Disconnect (MSD) is also known as Emergency service switch (ESS). It is a high-voltage connector with a fuse. In order to ensure the safety of people and vehicles when new energy electric vehicles are repaired, the power supply of the high-voltage system is disconnected by pulling out the MSD.It enables electrical isolation of high-voltage systems and also provides short-circuit protection.There are generally two types of MSD electrical part arrangements, one is located at the positive pole of the high-voltage power supply, and the other is located in the middle of the battery pack.

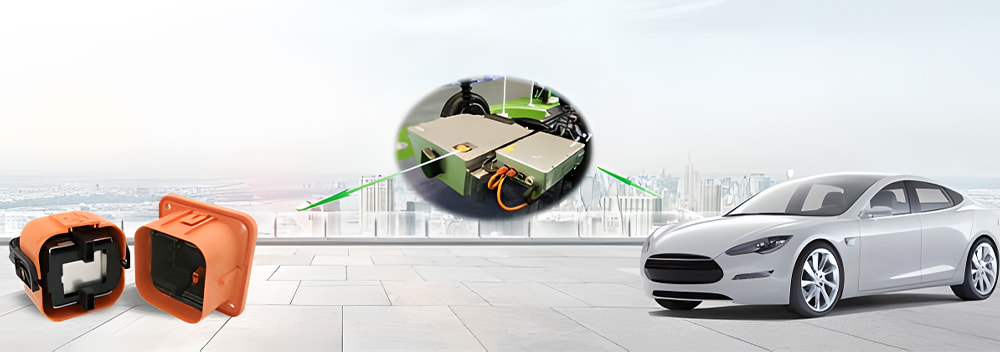

The MSD can be used to disconnect the high-voltage circuit easily without tools, and has a high-voltage interlock function, which is an important safety protection component. The reliability of the MSD obviously affects the safety of the whole vehicle and the maintenance personnel, so it needs to carry out a perfect performance test.It can be applied in new energy vehicle battery packs or high-voltage distribution cabinet assemblies.

The basic principle of MSD operation is that the MSD is installed in the main circuit with a built-in high voltage fuse and designed with a high voltage interlock. In the event of an external short-circuit, the fuse blows to cut off the high-voltage circuit.

When it is necessary to manually disconnect the high-voltage, the high-voltage interlock will be disconnected first, and then the high-voltage circuit will be disconnected.Therefore, in general, fuses, high voltage interlocking HVIL interfaces are essential for MSDs, in addition to seals, manual disconnect pullers, high voltage warning signs, and housing and fixing structures.

Features of MSD

1. MSD is a manual maintenance protection switch for EV high yoltage box or battery box.It can provide safe and reliable guarantee for the maintenance of electric vehicle power system.It can be used as maintenance protection switch and short circuit protection effect.

2. It is smaller than the general-purpose MSD, easy to assemble and disassemble, free from tool disassembly, and the detachable interlocking buckle has its own disassembly and assembly patent structure. The product is easy to repair during use and it is easy to replace the fuse.

3. Good shock resistance and high strength in the locking position.

4. Optional100A to 630A high current fuses.

5. This product is mainly used for high voltage, high current main line connection. Emergency power- off protection for the circuit.

Although MSD is only a small part of Pack, since this part involves the safety of the product, its design and selection are particularly important and should not be ignored.

Firstly, the MSD must be designed in such a way that manual disconnection can be achieved without any tools, and the number of connections must be at least 50, and probably more in practice. When the installation connection is completed, make sure that it meets the protection level of IPXXD (this needs to be jointly designed by MSD and battery pack companies), and meets IPXXB when disconnected (this is a requirement that needs to be fulfilled by the MSD itself), this is something that is very easy to be overlooked, and failure to meet the IPXXB means that the fingers can come into contact with high-voltage hazardous parts, and this is not allowed.

Secondly, the MSD installation is generally mounted on the lid of the box. And in order to ensure that the Pack meets the IP67 or IP6k9k airtightness requirements, the MSD itself must meet IP67 & IP6k9k. This needs to be considered as a basic parameter when selecting MSDs. And the supplier should be asked to provide the relevant reports for validation. At the same time, environmental aging during long-term use needs to be considered. A 1008-hour high-temperature aging test under 125︒C or 140︒C is commonly used. After the test is completed, the air tightness requirement of 28Kpa still needs to be met, so as to ensure that this component will last throughout the life of the Pack. IP reliability over the cycle.

In addition, the materials of MSD except Fuse and HVIL connectors are basically plastic, and it must be ensured that the material of MSD meets the fire resistance level of UL94 V0. Because the whole battery pack needs to be tested by fire, if the fire resistance level of MSD is not enough, the external fire will enter the pack from MSD, which is not allowed.

How to choose MSD

There are several key factors to consider when selecting an MSD:

Rated Voltage: If the maximum voltage of the PACK is above or below 400V, it should be selected to be greater than or equal to DC450V gear;

Load Continuous Current: The rated current of MSD should be greater than the load continuous current, for example, 2 times (the specific size should be determined according to the actual design).

Peak Load Current: The peak load current capability of the MSD needs to be greater than the peak load current;

Reaction time considerations: the fusing reaction time of the MSD should be less than the sticking time of the relay;

Mainly from the maximum voltage and electric current two parameters to carry out the division, which is conducive to both the engineering staff selection, but also to achieve lower costs.

MSD is similar to the safety gatekeeper of the battery pack, which needs to cope with the safety risks of high voltage and high current. Both externally to protect the safety of personnel and other components of the vehicle. And internally to protect the battery pack from the hazards of short-circuiting. And at the same time, the MSD needs to avoid unnecessary failures of the vehicle throughout its life cycle.

Safety is no small matter, and the importance of MSD cannot be ignored!