Battery Storage

The Ultimate Guide to Choosing the Perfect Forklift Battery Connectors

Forklift battery connectors are a crucial component in maintaining the efficiency and safety of your forklift operations. With a wide variety of connectors available in the market, it can be challenging to select the right one for your specific needs. In this article, we will guide you through the essential factors to consider when choosing the perfect forklift battery connector, ensuring optimal performance and longevity for your investment.

Understanding Forklift Battery Connectors

Forklift battery connectors serve as the link between the battery and the forklift’s electrical system, enabling the flow of electrical current necessary to power the vehicle. They come in various sizes, materials, and designs to cater to different battery capacities and forklift models. Selecting the right connector is vital to avoid issues such as overheating, voltage drops, and poor connections that can result in damage to the battery and decreased forklift performance.

Types of Battery Connectors

There are several types of forklift battery connectors available, but the most commonly used are:

- SB Connectors: These are the industry standard for heavy-duty applications, featuring a genderless design that allows for quick and easy connection and disconnection.

- Euro Connectors: Also known as DIN connectors, these are widely used in European forklifts and offer a compact, reliable connection.

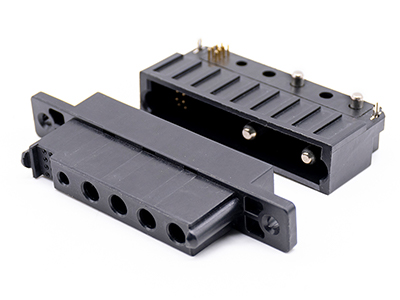

- Elecpeek Connectors: These connectors have been around for a long time and are known for their durability and reliability. They are available in various sizes and configurations to suit different applications.

Key Factors to Consider When Selecting Forklift Battery Connectors

To choose the right forklift battery connector, you need to take several factors into account:

1. Connector Size and Current Capacity

The size of the connector and its current carrying capacity are crucial factors to consider. Select a connector that can handle the battery’s maximum current output without overheating or causing voltage drops. The connector’s size should correspond to the battery cable size and the forklift’s power requirements. A common mistake is opting for a smaller connector to save costs, which can lead to poor performance and potential damage to the battery and forklift.

2. Material and Durability

The material used in the connector plays a significant role in its durability and performance. Connectors are typically made of copper or copper alloys, which provide excellent conductivity and corrosion resistance. Some connectors also feature silver-plated contacts for enhanced conductivity and reduced voltage drops. Ensure the connector’s material is suitable for your application and can withstand the rigors of daily forklift operations.

3. Connector Design

Consider the connector’s design and how it affects the ease of connection and disconnection. Genderless connectors, such as SB connectors, offer a hassle-free connection process, while connectors with distinct male and female ends may require more attention during installation. The connector’s design should provide a secure and consistent connection, minimizing the risk of disconnection during forklift operations.

4. Compatibility with Existing Equipment

It’s essential to select a connector that is compatible with your existing forklift battery and charging equipment. Ensure the connector’s size, voltage rating, and polarity match those of your battery and charger. Using incompatible connectors can lead to poor performance and potential damage to your equipment.

5. Ease of Maintenance

Choose a connector that is easy to maintain, clean, and inspect. Regular maintenance is critical in ensuring the connector’s optimal performance and longevity. Some connectors feature removable contacts, making it easier to clean and maintain the connection points.

Making the Final Decision

Now that you have a better understanding of the factors to consider when selecting the right forklift battery connector, you can make an informed decision based on your specific needs. Keep in mind that investing in a high-quality, reliable connector can save you time, money, and potential downtime in the long run.

If you’re still unsure about which connector to choose, consult with your forklift supplier or battery manufacturer for expert advice tailored to your specific requirements. With the perfect connector in place, you can ensure the smooth and efficient operation of your forklift, maximizing productivity and minimizing potential issues down the line.